Surface Treatment of Stainless Steels

Posted: May 06, 2015 Hits: 1419

1. Introduction of stainless steel categories

Main components of stainless steels are composed of various high quality metallic elements like Cr, Ni, Mo, Ti, etc. Commonly used stainless steels include chromium stainless steels (Cr≥12%) and Ni-Cr stainless steels (Cr≥18%; Ni≥12%). In terms of metallurgical structure, stainless steels can be categorized into austenitic stainless steels, such as 1Cr18Ni9Ti, 1Cr18Ni11Nb and Cr18Mn8Ni5, and martensitic stainless steels, such as Cr17 and Cr28. In addition, stainless steels can also fall into non-magnetic stainless steels and magnetic stainless steels.

2. Commonly used surface treatment of stainless steels

Commonly used surface treatment techniques of stainless steels include natural whitening process, mirror polishing process and coloring process.

(1) Natural whitening process: during machining process, stainless steels go through rolling, binding, welding and artificial fire heating treatment, producing black oxide scale which mainly contains NiCr2O4 and NiF. In the past, the black oxide scale was removed by strong corrosion method with hydrofluoric acid and nitric acid, but this removal method is gradually abandoned for its pollution to environment, harm to people's health and relatively strong corrosion.

(2) Mirror polishing process: based on the complexity of stainless steels and specific customer requirements, the process can be divided into mechanical polishing, chemical polishing and electrochemical polishing,

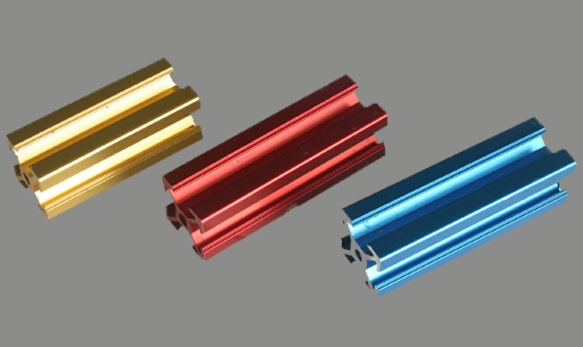

(3) Coloring process: after the process, stainless steels can have various floral designs with different colors. In addition, abrasion-resistant and corrosion-resistant performance of stainless steels can be improved.

3. Selection of surface treatment

The suitable surface treatment should be selected based on product structure, materials and different surface requirements.

Main components of stainless steels are composed of various high quality metallic elements like Cr, Ni, Mo, Ti, etc. Commonly used stainless steels include chromium stainless steels (Cr≥12%) and Ni-Cr stainless steels (Cr≥18%; Ni≥12%). In terms of metallurgical structure, stainless steels can be categorized into austenitic stainless steels, such as 1Cr18Ni9Ti, 1Cr18Ni11Nb and Cr18Mn8Ni5, and martensitic stainless steels, such as Cr17 and Cr28. In addition, stainless steels can also fall into non-magnetic stainless steels and magnetic stainless steels.

2. Commonly used surface treatment of stainless steels

Commonly used surface treatment techniques of stainless steels include natural whitening process, mirror polishing process and coloring process.

(1) Natural whitening process: during machining process, stainless steels go through rolling, binding, welding and artificial fire heating treatment, producing black oxide scale which mainly contains NiCr2O4 and NiF. In the past, the black oxide scale was removed by strong corrosion method with hydrofluoric acid and nitric acid, but this removal method is gradually abandoned for its pollution to environment, harm to people's health and relatively strong corrosion.

(2) Mirror polishing process: based on the complexity of stainless steels and specific customer requirements, the process can be divided into mechanical polishing, chemical polishing and electrochemical polishing,

(3) Coloring process: after the process, stainless steels can have various floral designs with different colors. In addition, abrasion-resistant and corrosion-resistant performance of stainless steels can be improved.

3. Selection of surface treatment

The suitable surface treatment should be selected based on product structure, materials and different surface requirements.